WeChat ID

aaronpk_tv

#prusa

-

Guaranteed fix for your Prusa Mini's extrusion issues : prusa3d (www.reddit.com)"Basically, it means heat creeps up from the melt zone to parts that should really be cold. This heat transfer is mostly through the heat break. But why is it a problem if plastic gets hot here? Let's say we are printing some PLA filament, at 215c, causing the plastic in the heat break to be at 70 degrees celsius.

At 70 degrees, PLA is already quite soft. Because filament is fed from the top, the hot plastic in the heat break gets compressed, and will expand sideways. It will form to all the tiny imperfections in the metal, forming a kind of mechanical bond, hereby creating resistance for the extruder, which will have to exert more force to push filament through the hot end.

If you print an object in vase mode, meaning you only print the outline, going up in one continous spiral without stopping, the plastic doesn't get the time to form to the metal. Additionally, you're constantly pushing cold filament down. This doesn't create much opportunity for heat creep.

But most prints involve retractions, where the filament is temporarily pulled back by the extruder a few millimeters, to prevent it from oozing out the hot end during non-printing travers of the hot end. What this means is that you're pulling hot plastic upwards, hereby giving the hot filament the opportunity to transfer heat to cold parts. With bowden (remote) extruders this is more prominent because those often have retraction values of several mm (3.2mm in the case of the Prusa Mini).

When the extruder pushes filament but you have this mechanical bond/semi-clog in your hot end because of heat creep, then at first no plastic comes through the nozzle. Tension will build up before the clog, in the case of the Mini mostly in the bowden tube, where the filament will compress. This will result in underextrusion, and then when the clog releases, all the build up pressure will cause overextrusion." -

-

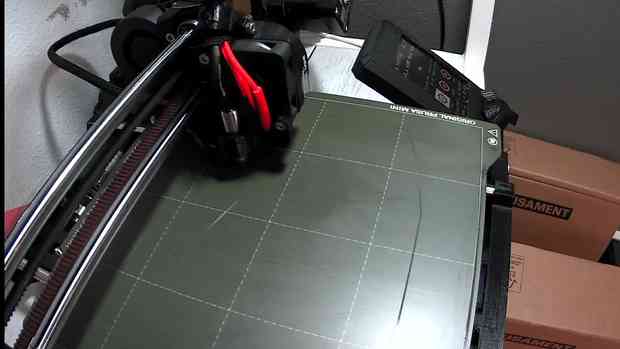

Aaron's 3D Printer has just started streaming on their #owncast server! Check them out at:

https://printer.aaronpk.tv.Watch Aaron's 3D printer at work!

-

Aaron's 3D Printer has just started streaming on their #owncast server! Check them out at:

https://printer.aaronpk.tv.Watch Aaron's 3D printer at work!