WeChat ID

aaronpk_tv

#3DPrinting

-

DDD Printable Wall Control System by luma | Download free STL model | Printables.com (www.printables.com)

-

-

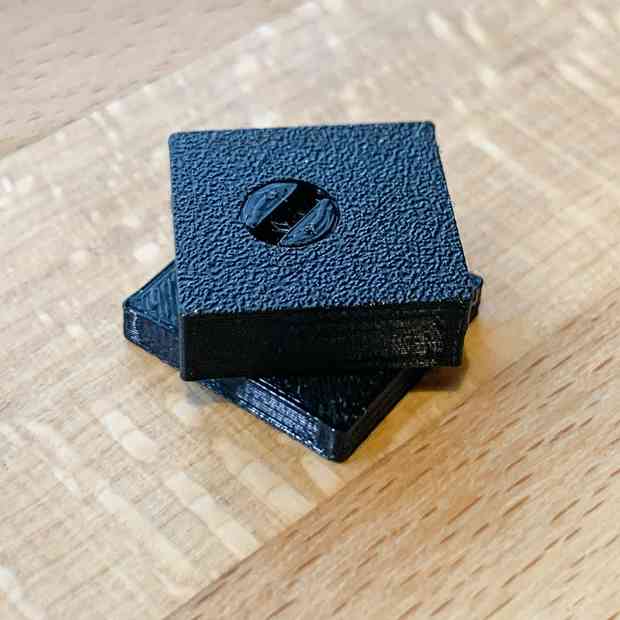

Have you ever used Carbon Fiber filament?

Incredibly strong parts! Well worth the extra cost!

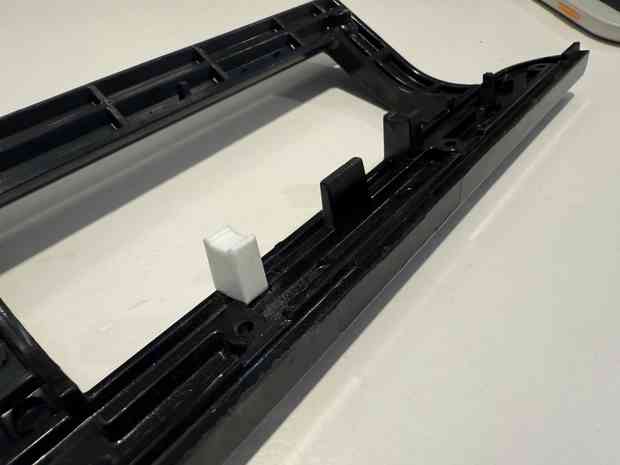

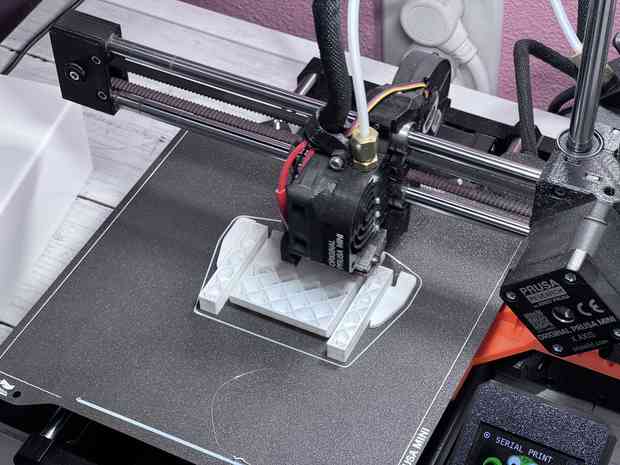

Below the side and top handles of our #YoloboxPro Cage https://pk1.tv/pk1-yolobox-cage/ are now available also in Carbon Fiber!

#3Dprinting #AdditiveManufacturing #LiveStreaming

-

Print in Place Geared Hinge by E. Soderberg | Download free STL model | PrusaPrinters (www.prusaprinters.org)